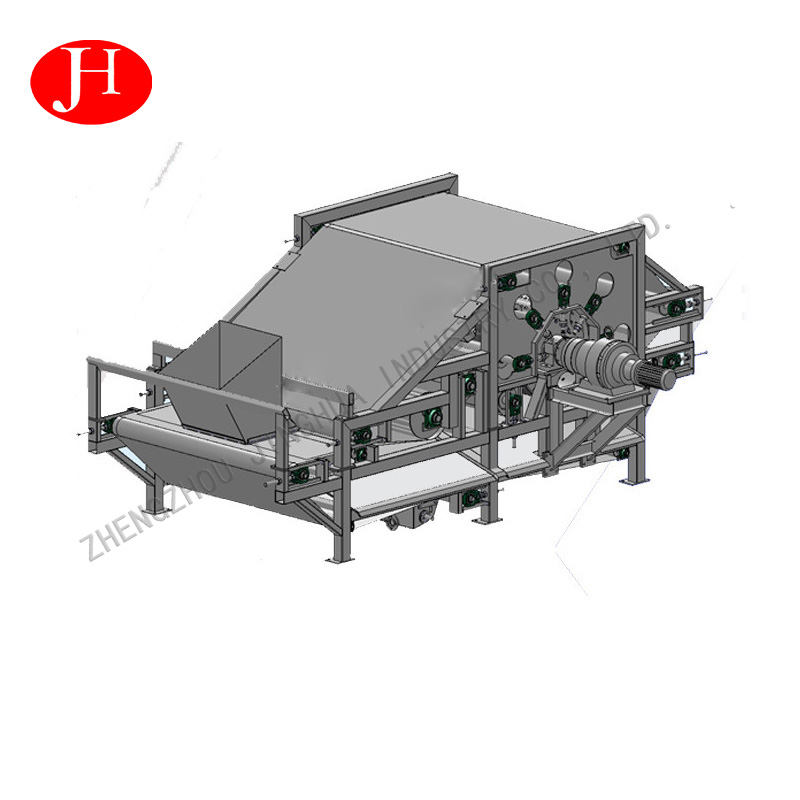

Iimveliso

I-Fiber Dehydrator ye-Start Processing

Iiparamitha eziphambili zobugcisa

| Umzekelo | Amandla (Kw) | Ukuhluza ububanzi bentambo (mm) | Ukuhluza isantya somtya (Nksk) | Umthamo(Ngaphambi kokuphelelwa ngamanzi emzimbeni)(kg/h) | Ubungakanani (mm) |

| DZT150 | 3.3 | 1500 | 0-0.13 | ≥5000 | 4900x2800x2110 |

| DZT180 | 3.3 | 1800 | 0-0.13 | ≥7000 | 5550x3200x2110 |

| DZT220 | 3.7 | 2200 | 0-0.13 | ≥9000 | 5570x3650x2150 |

| DZT280 | 5.2 | 2800 | 0-0.13 | ≥10000 | 5520x3050x2150 |

Iimbonakalo

- 1Imveliso iphuhliswe ngokuzimeleyo yinkampani, kunye neenzame zophando lwezenzululwazi zeHenan University of Technology.

- 2Umxhesho omile okwe-Wedge unokuqinisekisa imathiriyeli esasazwa ngokulinganayo kumtya wokuhluza kunye nobukhulu obuhlengahlengiswayo.

- 3Inkqubo yokuqengqeleka ephelelwe ngamanzi yenziwe ityhubhu engenamthungo kwaye isongelwe ngerabha ekumgangatho ophezulu onganxibiyo, Ithembekile ngobomi benkonzo ende.

Bonisa iinkcukacha

Intsalela yeetapile ihopper ibekwe ngokutyibilikayo kwibhanti yokucoca esezantsi ngecandelo lokutyisa elimise okwe wedge.

Emva koko intsalela yezambane ingena kwindawo yokucinezela kunye nokucima. Intsalela yeitapile isasazwa ngokulinganayo phakathi kwamabhanti amabini okucoca kwaye ingena kwindawo ye-wedge kwaye iqala ukucinezela kunye nokukhupha amanzi. Emva koko, intsalela yezambane ibanjwe ngamabhanti amabini okucoca, aphakama kwaye awele amaxesha amaninzi. Izikhundla zemigangatho yangaphakathi nangaphandle yeebhanti ezimbini zokucoca kwi-roller zihlala zitshintsha, ukwenzela ukuba intsalela ye-potato layer ihlale ihlanjululwa kwaye ichebe, kwaye ubuninzi bamanzi buxinzelelwe phantsi koxinzelelo lwebhanti lokucoca. Emva koko intsalela yezambane ingena kwindawo yokucinezela kunye nokucima amanzi. Ngaphantsi kwesenzo se-roller ezininzi ezicinezelayo kwindawo ephezulu ye-roller yokuqhuba, i-dislocation shear kunye ne-extrusion ziqhubeka ziveliswa.ngexesha lokucinezela inkqubo, i-potato dregs isuswa ngokulula kwibhanti yokucoca.

Intsalela yezambane ithunyelwa kwisixhobo sokukrala ngokusebenzisa i-roller ebuyisela umva, kwaye emva kokuchithwa kwesixhobo sokukrala, ingena kwicandelo elilandelayo.

Ububanzi beSicelo

Iitapile eziswiti, isitatshi setapioca, isitatshi setapile, isitatshi sengqolowa, isitatshi sombona, i-ertyisi, njl. njl. (ukumiswa kwestatshi) amashishini okuvelisa istatshi.